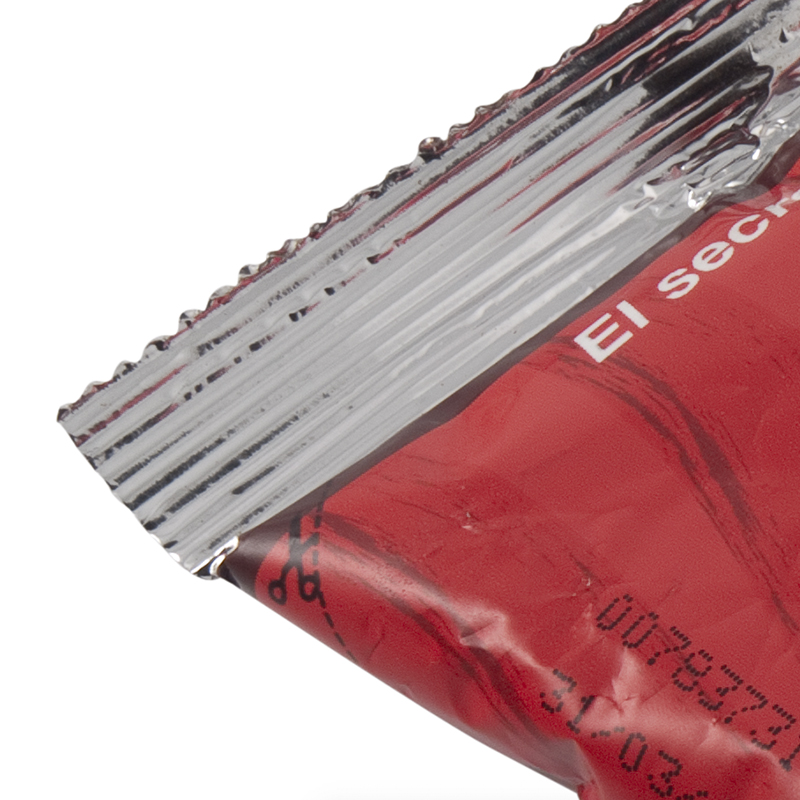

Bags

Eye-catching customized bags in multiple formats that extend your product’s shelf life: pillow pack, central vertical seal, 3-sealed, large format and modified atmosphere (MAP, or vacuum sealed).

Flexible Product Processes:

- Only high quality raw materials, including: aluminum, polypropylene, polyethylene, polyester, cellophane, nylon and paper

- Flexographic and rotogravure high graphic printing

- Matte or glossy finishes

- Flexible minimums

- Expertise in different types of lamination

- Up to seven layers of co-extrusions

- Experts in guaranteeing your product’s shelf life

- In-house pre-press

- Multiple signals in low, medium and high velocity

- Custom bags:

- In different shapes and types: pouches or doypack, rolls for sachets, pillows and large format bags.

- Accessories include: pre-cut laser, easy-open, zipper and degassing valve. Dies for custom shapes and handles.

- Product delivered in rolls or individual bags.